Product description

1.) layers for each unit:1-7layers

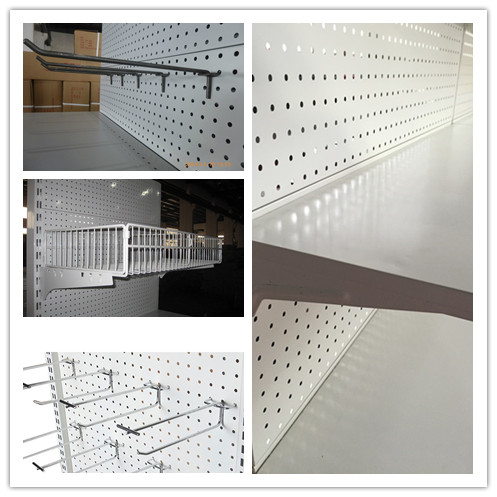

2). Surface treatment:plastic spraying

3). different thickness,size,layers,colors are available

4). easy to assemble and dismantle

5). weight capicity:50-120kgs per layer

6). material:high grade of cold roll steer

7). package: standard export carton

8). OEM design are welcome

Perforated grocery store shelf retail display stand punch hole racks pegboard gondola shelving

Our advantage:

*factorty direct sale

*perfect after-sales service

*offer product installation guide video

*Any color and size can be provided

*High quality, felixble delivery

*ISO standard, large capacity

*15 years of rich trading experience

*Obtained various international quality certifications

Shelf technology

1 rolling mill

There are many types of roll mills. There are smart high-end machines similar to those used in Tengkang shelves, as well as traditional and old machines used in small factories or workshops. Its main function is to roll a certain width of steel strip into a certain length of the required shape, such as shelf columns, shelf beams, etc. This is also an important step in shelf production.

2. Positioning and punching

According to actual needs, roll forming materials and punch out the required holes when necessary, such as the inverted eight holes or diamond-shaped holes of heavy-duty racks, and the round holes on the cross brace. The positioning of the punching is strictly in accordance with the design drawings to ensure the consistent and effective combination of the entire shelf project.

3 Bending (steel plate)

If the shelf has steel plates, the steel plates need to be bent inward. One is to effectively fix the steel plate on the beam, and the other is to enhance the load-bearing capacity of the steel plate.

4 Welding and grinding

Machining parts need to be welded together for welding treatment, such as shelf columns and pedals, beams and grippers. This requires welding in accordance with relevant national standards to ensure welding strength and capability. After the welding is completed, the welding seam should be polished to enhance the aesthetics of the shelf and improve the safety of the shelf.

5 Surface treatment

The surface treatment of convenience store shelves includes pickling, phosphating, electrostatic spraying, constant temperature curing, etc. In addition to the above processes, there are also packaging and installation.

-------------------------------------------------------------------

FAQ:

Q: Are you trading company or manufacturer?

A:We are manufacturer.

Q: How long is your delivery time?

A: Generally, can ship the goods in 20-25 days after payment.

Q: Do you provide samples? Is it free or extra?

A: Yes,can provide, as normal it need charge 3 times as regular price.

Q: What is your terms of payment?

A: 30% T/T in advance, balance before shipment.